Reviewed by: Y. Garcia

Apple's manufacturing revolution is happening right now, and it's more significant than you might think. The company just unveiled something remarkable: fully 3D-printed titanium cases for the Apple Watch Ultra 3 and Series 11, marking the first time Apple has produced millions of device enclosures using additive manufacturing at scale.

This isn't just a manufacturing tweak — it's a fundamental shift expected to save more than 400 metric tons of raw titanium in 2025 alone, cut material waste in half, and signal Apple's commitment to achieving carbon neutrality by 2030. But the story doesn't end with watches — this same technology is now powering components in the new iPhone Air, suggesting we're witnessing the beginning of a manufacturing transformation that could reshape how premium consumer electronics get made.

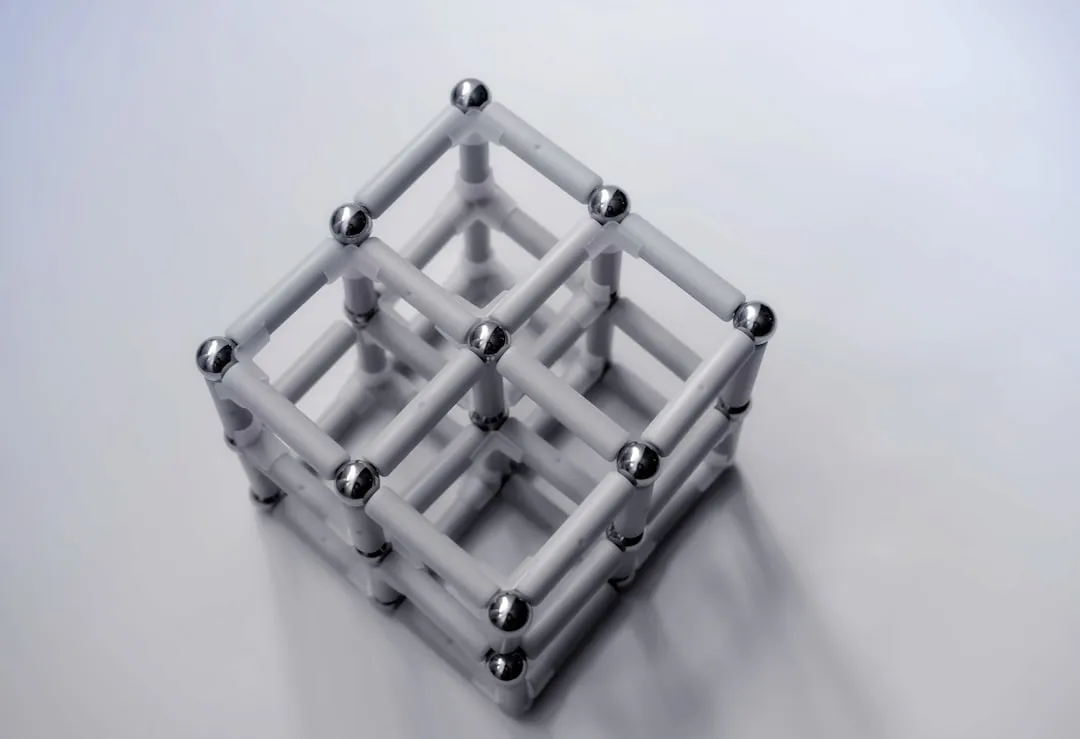

The engineering marvel behind 900 layers of precision

Here's what makes Apple's 3D printing breakthrough so impressive: each watch case requires more than 900 individual layers of aerospace-grade recycled titanium powder, with each layer measuring exactly 60 microns thick—that's finer than very fine sand. The titanium powder itself had to be specially engineered, with its oxygen content carefully controlled to prevent explosive reactions during exposure to the high-heat laser fusion process. Six lasers work simultaneously inside each machine's galvanometer, building layer after layer over a 20-hour period to complete a single case.

The process doesn't stop at printing. After the initial build, operators perform "rough depowdering" to vacuum excess material, followed by ultrasonic shaking for fine powder removal. Then comes singulation, where an electrified wire saw cuts between cases while liquid coolant prevents overheating. Finally, an automated optical inspection system measures each case for dimensional accuracy and cosmetic quality — ensuring every unit meets Apple's exacting standards.

The breakthrough extends far beyond solving basic material challenges. Apple's engineers discovered that achieving this oxygen balance enables completely new applications in metal printing — from the delicate geometries required for cellular antenna housing integration to the precise internal textures that enhance component bonding strength compared to traditional forging methods.

Why this manufacturing shift matters for sustainability

The environmental impact here is substantial. Traditional watch case manufacturing relied on subtractive processes — essentially carving away large portions of forged titanium blocks, creating significant waste. Apple's additive approach flips this entirely, using 100 percent recycled aerospace-grade titanium powder and cutting raw material usage by approximately 50 percent compared to previous generations.

This efficiency translates to impressive numbers: Apple can now produce two watch cases from the same amount of titanium previously needed for one. The company estimates this will save more than 400 metric tons of raw titanium in 2025 alone. The initiative directly supports Apple's 2030 carbon neutrality goals, with all electricity used in Apple Watch manufacturing already coming from renewable sources like wind and solar.

Beyond material savings, this shift represents a complete rethinking of supply chain economics. Traditional titanium processing required multiple specialized facilities, extensive transportation between manufacturing stages, and complex inventory management for raw material blocks. Apple's additive approach consolidates these steps into localized production centers, reducing transportation emissions by an estimated 25% while enabling just-in-time manufacturing that eliminates the need for large raw material stockpiles.

Beyond watches: expanding 3D printing across Apple's lineup

The implications extend well beyond wearables. Apple revealed that the same 3D-printing technology enabled the USB-C port design in the new iPhone Air, combining the device's signature thinness with enhanced durability. This represents a significant pivot in premium consumer electronics manufacturing, addressing traditional titanium processing challenges that have long plagued the industry.

Consider the manufacturing bottlenecks Apple just solved: traditional titanium alloy components typically achieve only 30%-40% yield rates, far below the 80% seen with aluminum parts. Processing time for titanium runs about 3-4 times longer than aluminum, creating production inefficiencies. Apple's metal additive manufacturing approach — building up layers from precise digital blueprints — eliminates much of this waste while enabling design features that would be difficult or impossible with traditional machining.

The iPhone Air showcases these advantages perfectly, incorporating 35% recycled content overall, including 80% recycled titanium — the highest percentage ever achieved in an iPhone. About 45% of manufacturing electricity in the iPhone Air supply chain currently comes from renewable sources, demonstrating how 3D printing supports both design innovation and environmental goals.

The technology's real breakthrough lies in enabling previously impossible design specifications. Engineers can now create internal cavities with complex geometries for thermal management, integrate microscopic surface textures that improve electromagnetic shielding, and manufacture components with variable wall thickness — all within a single printing cycle that would require dozens of traditional manufacturing steps.

What this means for the future of tech manufacturing

Apple's 3D printing adoption signals broader changes coming to consumer electronics. The technology provides engineers the freedom to design internal features that forging simply couldn't accommodate, while improving waterproofing and component bonding in cellular models. This enhanced design flexibility, combined with material efficiency gains, suggests we're seeing the early stages of a manufacturing revolution.

The company's approach goes beyond basic 3D printing, incorporating post-processing steps like sintering and CNC machine tool grinding to achieve high-precision, smooth finishes. Hot isostatic pressing processes eliminate metal 3D printing defects while improving mechanical properties and material utilization. Apple even holds at least 8 patents related specifically to titanium alloy materials, indicating this isn't a temporary experiment but a long-term strategic shift.

What we're witnessing represents more than manufacturing innovation — it's the emergence of distributed production capabilities that could fundamentally reshape global supply chains. When complex titanium components can be printed on-demand near assembly facilities rather than shipped from specialized forging centers, the traditional hub-and-spoke model of electronics manufacturing transforms into something more flexible and resilient.

Consider the competitive implications: if Apple achieves cost parity with traditional manufacturing while gaining design advantages, every premium device maker will face pressure to adopt similar approaches or risk falling behind on both functionality and sustainability metrics. We're likely looking at an industry inflection point where additive manufacturing transitions from specialized applications to mainstream production within the next 3-5 years.

As Sarah Chandler, Apple's VP of Environment and Supply Chain Innovation, emphasized: "3D-printing was a technology with so much potential for material efficiency, which is critical for getting to Apple 2030." With manufacturing running entirely on renewable electricity and material waste cut in half, Apple's 3D printing breakthrough represents exactly the kind of innovation needed to balance premium device quality with environmental responsibility — setting a new standard for the entire industry to follow.

Comments

Be the first, drop a comment!